For Dalian extrusion products, the structure, type and specification of extruder can be different with material characteristics, product size and output requirements; The structure, shape and size of the machine head are designed and manufactured according to the specific products; The cooling and setting method depends on the product variety and material properties; Other auxiliary machines will also have many differences. However, each process link in the above block diagram is basically the same.

Extrusion is applied to the processing of thermoplastic and rubber. It can be used for batching, granulation, rubber filtration, etc. it can be used for continuous production and manufacture various continuous products, such as pipe, profile, plate (or sheet), film, wire and cable coating, rubber tire tread, inner tube, sealing strip, etc. with high production efficiency. In the production of synthetic resin, extruder can be used as reactor,.

In the rubber industry, extruders with different compression ratios can be used to plastic natural rubber. The compression ratios of extruders with different materials are somewhat different. The "thermosetting" materials that can be extruded are usually cross-linked thermoplastic materials (or mixtures), which have large molecular weight, It has certain melt or body strength at processing temperature.

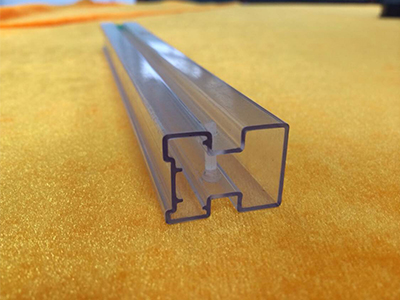

Therefore, the shape can still be maintained after leaving the extruder die, and then vulcanization / crosslinking can be completed in the subsequent section. There are many extruded vulcanized products, such as rubber sealing strip, rubber hose, crosslinked polyethylene cable sheath, etc. Thermoplastic refers to that after plastic processing, curing and cooling, it can still achieve fluidity after reheating, and it can be processed and formed again, that is, it has good reprocessability and recycling. For example, our common PVC, PE, PP, ABS and other common plastics.