In practical applications, the application range of extrusion molding technology is very wide, mainly applied in fields such as wires and cables, components, building materials, plastic bags, and waste plastic recycling. For example, wires and cables need to be coated with materials such as PVC and PE during the manufacturing process, and the protection and insulation functions of the cables need to be achieved through extrusion molding; However, the recycling of waste plastics requires the use of extrusion molding to process and recycle materials, so that they can be reused.

Extrusion molding is the process of heating and melting thermoplastic materials, which are then high-pressure extruded through the screws of an extruder. After further processing by a mold, various shapes of plastic products are formed. The basic principle is that thermoplastic materials are fed into the barrel of the extruder through a hopper, pushed by a screw towards the direction of the mold, and formed into products with different shapes through the mold. During this process, it is necessary to control various parameters such as the temperature of the heating zone, extrusion speed, and stretching ratio. After the extruder stops extruding, the formed product can be processed and processed after being released from the mold.

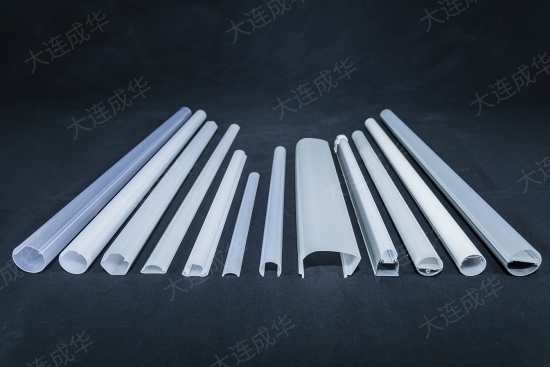

Summary of Dalian Extrusion Molding Application

(1) Plastic products: such as plastic barrels, plastic boxes, plastic chairs, and other plastic products.

(2) Pipe manufacturing: various pipes such as water pipes, gas pipes, cable pipes, plastic drainage pipes, etc.

(3) Plastic packaging: various types of plastic packaging, such as plastic film, plastic bags, color printing film, etc.

(4) Automotive industry: various plastic parts used in automobiles, such as car door panels, car seats, etc.

(5) Construction industry: various plastic products used in construction, such as plastic doors and windows, plastic wall panels, etc.

(6) Electronic and electrical industry: plastic products for various electronic and electrical appliances, such as plastic product casings, plastic switches, plastic sockets, etc.

Extrusion molding is a common molding method, which involves heating and melting plastic materials under high temperature and pressure, and then pressing the molten plastic materials through the mold through the extrusion head to form the desired product shape. The extrusion molding process is simple, with high molding efficiency, and can be used to produce various shapes of plastic products, such as pipes, plates, profiles, ribbons, etc.

The equipment for extrusion molding mainly includes an extruder, heating system, cooling system, tensile measuring instrument, etc. The extruder is the core device, usually composed of multiple components such as the feeding device, screw device, heating, cooling, and control system. Commonly used extruders include single screw extruders, twin screw extruders, hybrid extruders, and other types. The heating system is mainly used to heat plastic raw materials to reach a molten state. The cooling system is used to control the cooling rate of the extruded formed product to ensure product quality.