The price of extrusion molding products, the extrusion molding process conditions of chlorinated polyvinyl chloride pipe are similar to those of ordinary polyvinyl chloride pipe, but the slight difference is that the quality requirements of equipment parts for extrusion molding are higher; The fluctuation range of process temperature shall be controlled strictly.

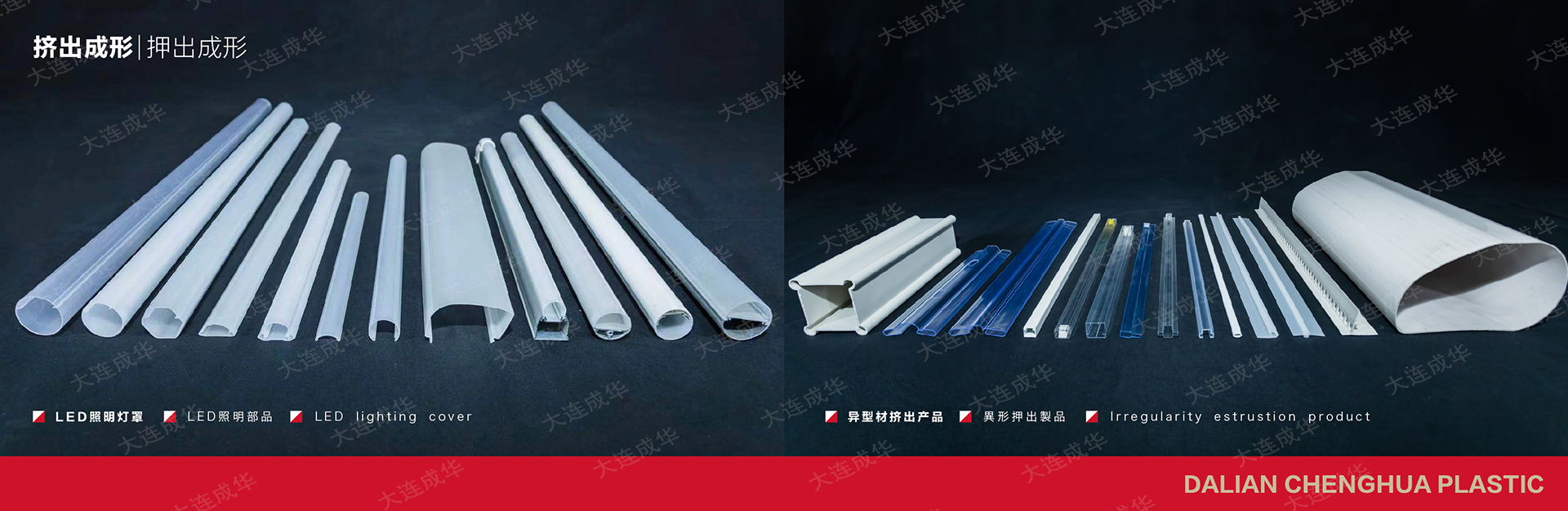

Extruded products, Extrusion process sequence of chlorinated polyvinyl chloride pipe: measure various raw materials respectively according to the material formula for CPVC pipe forming → put the raw materials into the mixer and mix evenly → cool and mix the mixed materials evenly → plasticize the raw materials in the extruder to make them melt → mold forming pipe blank → vacuum sizing cooling and setting → cooling the pipe in the cooling water tank → traction → trademark printing → cutting → pipe end expansion Export → inspection → packaging and warehousing. The same direction rotation type shall be selected, the working speed shall be lower than 20R / min, and the molding die temperature shall be about 200 ℃; If the powder is extruded, the counter rotating twin-screw extruder shall be selected for extrusion.

When the single screw extruder extrudes plasticized raw materials, the screw can be adjusted by circulating oil, and the equipment shall have a good exhaust device; It is appropriate to use circulating water or circulating oil for cooling the barrel, and pay attention to control the process temperature fluctuation at about ± 5 ℃. It is more suitable to extrude CPVC powder with ordinary parallel twin-screw extruder. No perforated plate is added between the barrel of the extruder and the forming die; The working place of the screw shall be equipped with overload protection device.