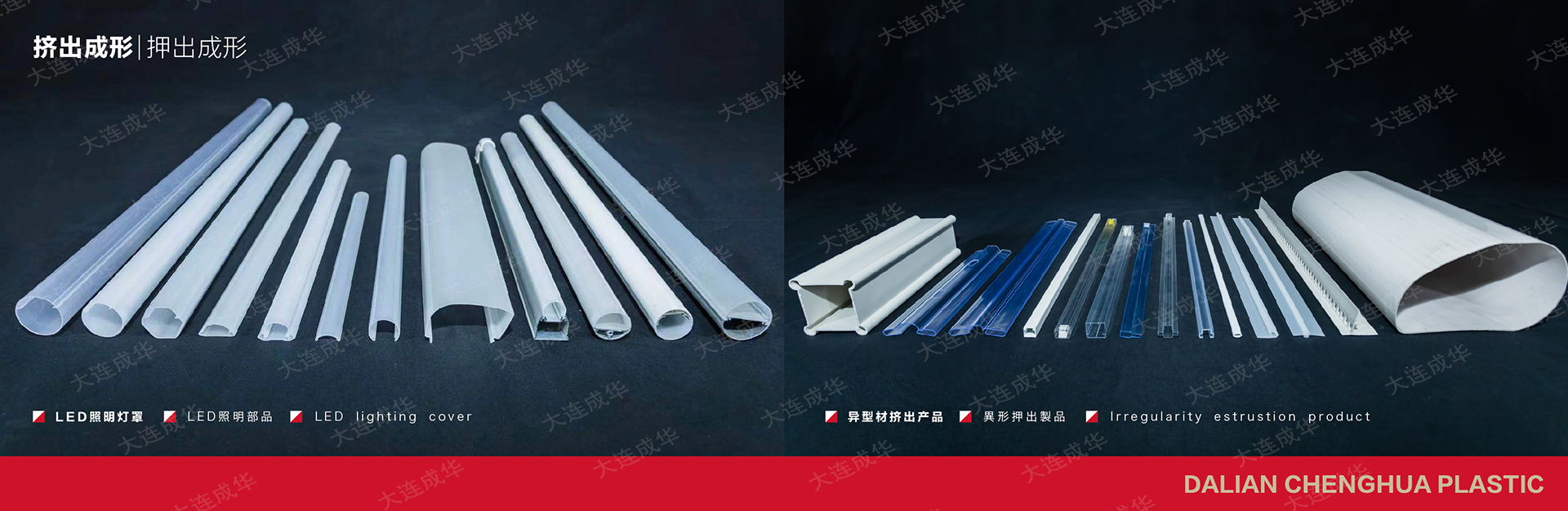

Extrusion molding product technology has a wide range of applications, whether it is used in the long night of rubber, plastic, fiber and other related processing, especially in the production of plastic products. Most thermoplastic plastics and some thermosetting plastics can be processed by this method. In addition to directly molding products, extrusion method can also be used for mixing, plasticization, granulation, coloring, blank forming and other processes.

The outstanding feature of extrusion blow molding machine is continuous production. It can produce any length of pipe, plate, bar, profile, film, cable and monofilament according to needs. Compared with the injection molding machine calender, the extrusion molding process has the advantages of simple equipment, less investment, lower manufacturing process, lower equipment cost, convenient installation and commissioning process, small floor area, and relatively simple requirements for plant and supporting facilities.

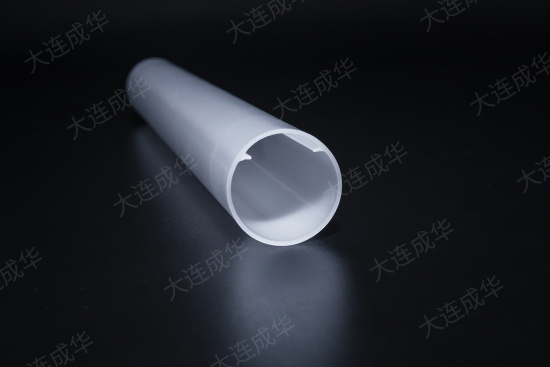

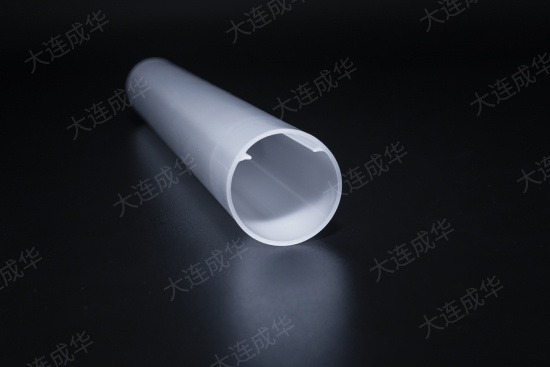

Extrusion molding wholesale, the raw material embryo is extruded into the mold. This molding method ensures the wall thickness of the embryo to a great extent, thus providing a good production foundation for the products; The molding method is very friendly to most plastic raw materials, so most plastic raw materials can be used for production. The so-called plastic extrusion blow hollow molding machine adopts the extrusion + blow molding method.