Specializing in the production of extrusion products, the quality of extruded profiles depends on the extrusion die. The extrusion die is mainly composed of machine head and setting device. The rationality of its structural design is the decisive factor to ensure the molding quality of plastic parts. The granular or powdery plastic is added into the hopper, and the heated plastic is transported forward along the spiral groove of the screw under the action of the rotating screw of the extruder.

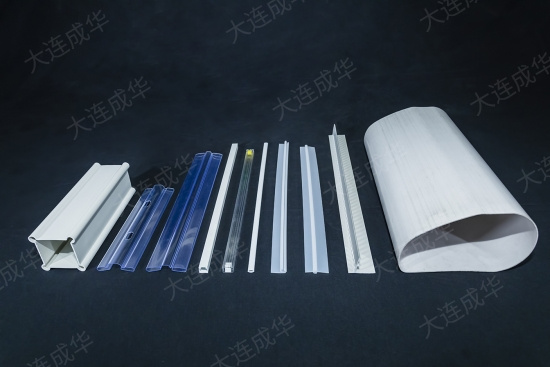

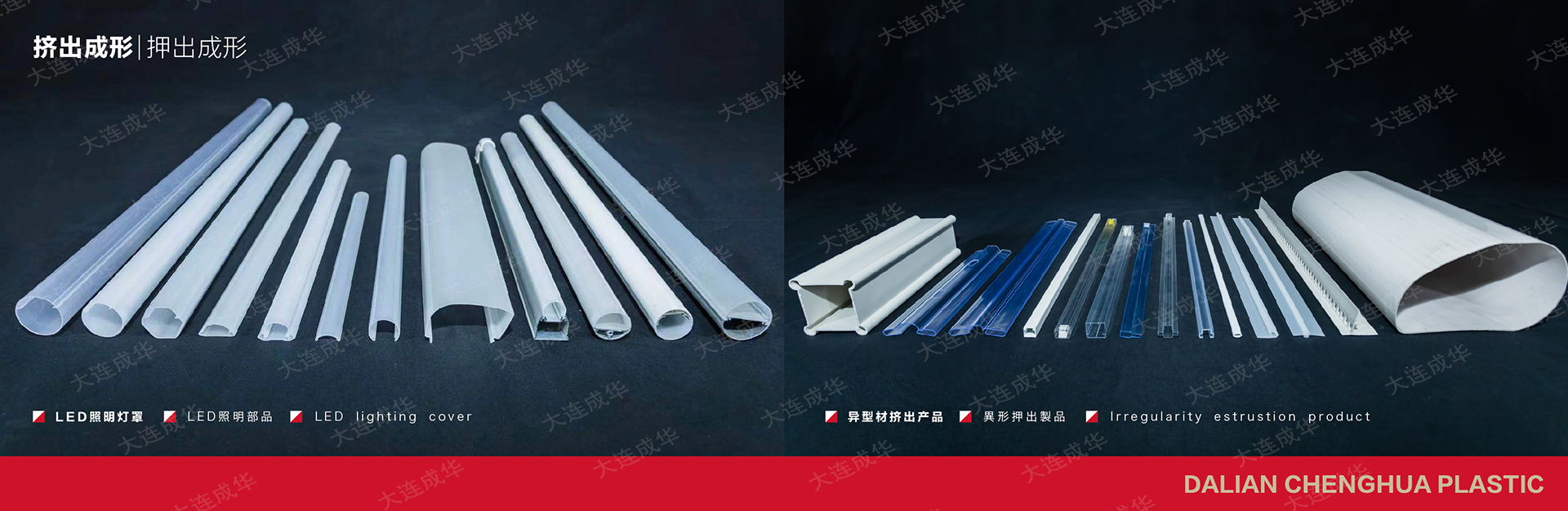

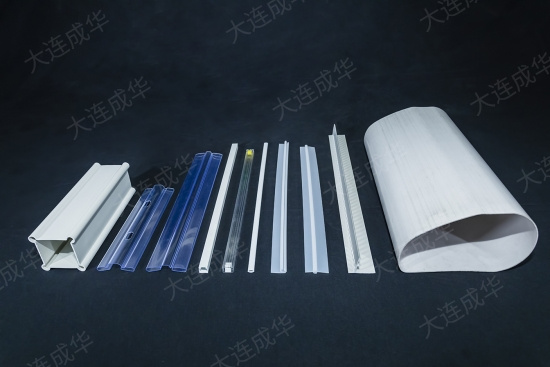

At this time, the plastic is constantly subjected to the shear friction heat between the screw and the material, between the material and the material and between the material and the barrel, and gradually melts into a viscous flow state. Then, under the action of the extrusion system, the plastic melt passes through the extrusion die (die) with a certain shape and a series of auxiliary devices (setting, cooling, traction, cutting and other devices), so as to obtain the plastic profile with a certain cross-section shape.

Specializing in the sales of extrusion products, viscous plastic melt, driven by the screw force of extruder, obtains continuous profiles with the same section and die shape through the die with a certain shape. Under the action of barrel temperature of extruder and rotary compaction and mixing of screw, plastic raw materials change from powder or granular to viscous fluid.