Companies selling extrusion products use molding or lamination methods with molding pressure equal to or lower than 1.4 MPa. The low pressure molding method is used to manufacture reinforced plastic products. Reinforcement materials such as glass fiber, textile, asbestos, paper, carbon fiber, etc. Most commonly used resins are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins. Low pressure forming includes bag pressing method and spraying method.

Bag press molding: a method of making reinforced plastic between rigid mold and elastic bag uniformly compressed by receiving fluid pressure with the help of elastic bag (or other elastic diaphragm). According to different methods of causing fluid pressure, it can be generally divided into pressurized bag forming, vacuum bag forming and autoclave forming. Reprocessing of formed plastic products or profiles as required, such as machining, connection, modification, etc. Machining: sawing, shearing, punching, turning, planing, scraping, milling, drilling, grinding, polishing, sandblasting, kneading, thread processing and other surface decoration: coating, solvent brightening, coating, printing, color painting, hot stamping, vacuum coating, spraying, electroplating, etc.

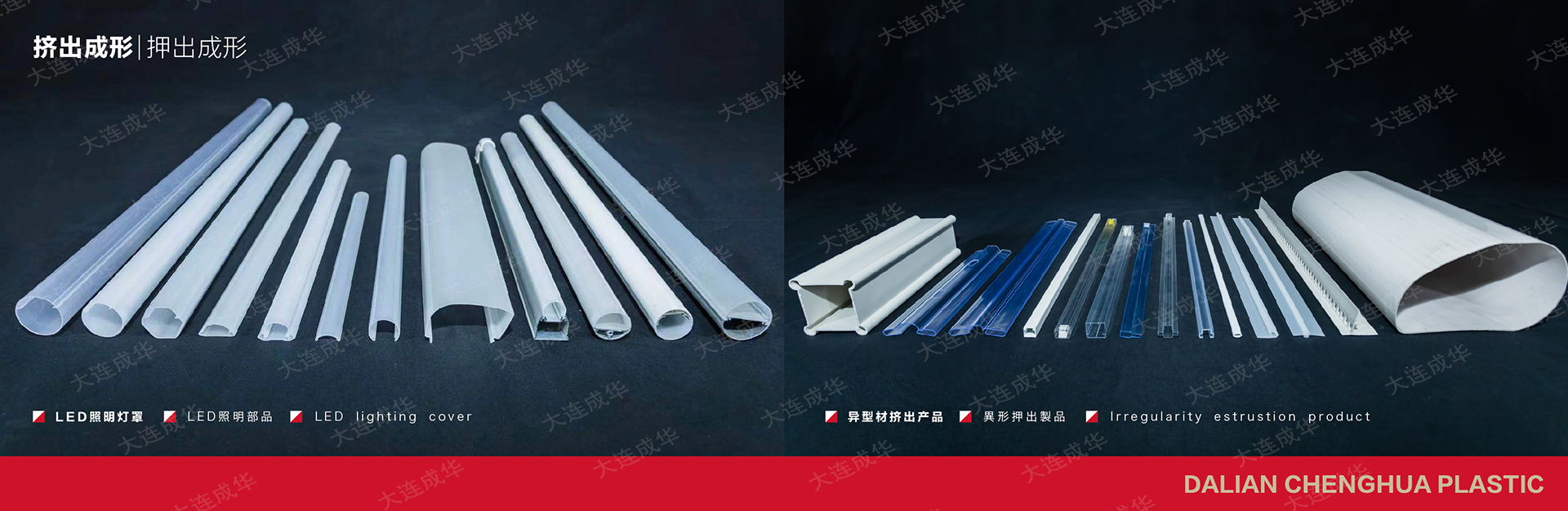

Manufacturers selling extrusion products. Multi screw extruders generally refer to extruders with three or more screws, which are usually designed to achieve better mixing processing effect. Compared with single screw and twin screw, its market application is much less. Planetary screw extruder is a multi screw extruder which has attracted more attention in the market in recent years. It is especially suitable for the extrusion processing of general plastics. As a mixed feeder for molding processing, it has better effect.