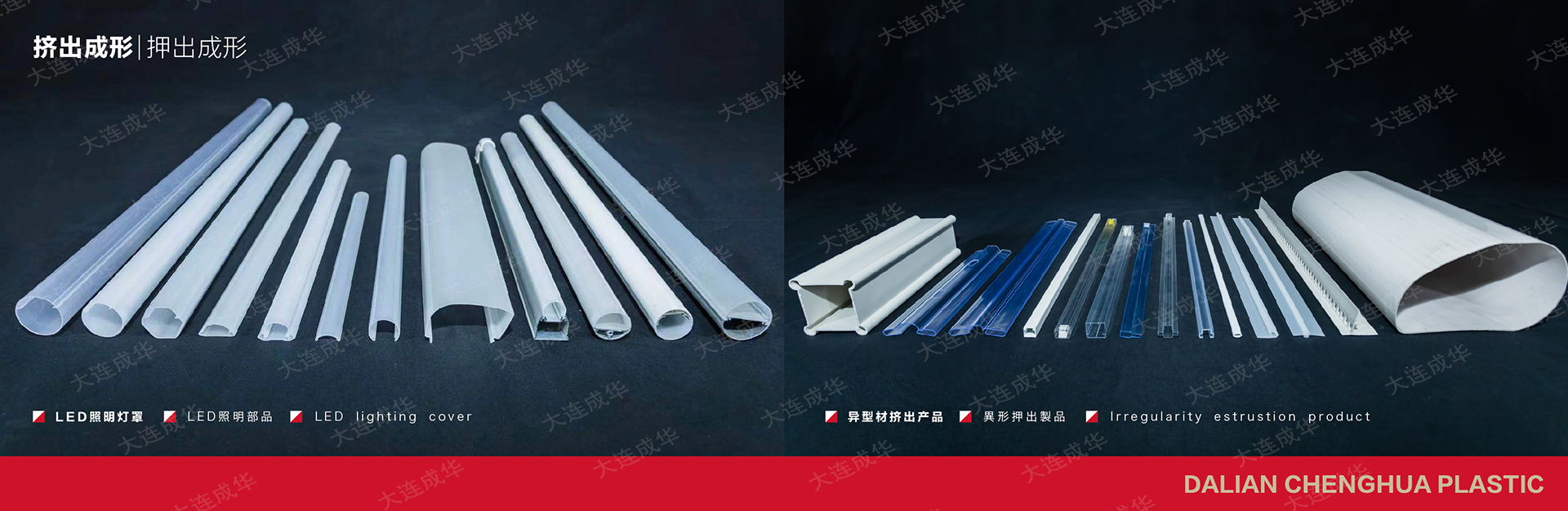

It is better to buy extrusion products. The pipe extrusion processing is mainly carried out by the extruder to stably transport the plastic to the pipe head after heating, plasticizing and melting. The pipe blank is formed by the head. Under the action of the traction device, the required geometric shape and size accuracy are achieved through the setting and cooling device, and then cut, packaged and stored in the warehouse. Plastic products are widely used molding methods.

Rubber injection molding and plastic injection molding are usually used for products. Injection molding can also be divided into injection molding, molding and die casting. Injection molding machine (hereinafter referred to as injection machine or injection molding machine) is the main molding equipment that uses plastic molding molds to make thermoplastic or thermosetting materials into plastic products of various shapes. Injection molding is realized through injection molding machines and molds. This is a processing method in which materials are heated and plasticized by the action between the extruder barrel and the screw, pushed forward by the screw, and continuously made into various cross-section products or semi-finished products through the machine head.

Choose which extrusion molding product is better, just choose an ordinary injection molding machine. When the product thickness is within the range of 2.3 ~ 3mm, the flow length and thickness ratio is 200:1, the demoulding slope is not less than 1 °, the depth of the exhaust slot of the exhaust hole is less than 0.03mm, and the temperature difference between the two molds is less than 3 ~ 6 ℃. The specific injection molding process conditions are as follows: the molding temperature is 180 ~ 215 ℃, the injection pressure is 30 ~ 150MPa, and the mold temperature is lower than 70 ℃.