The characteristics of extrusion blow molding in reliable extrusion molding factory are simple equipment, low equipment investment cost, wide selection range of molds and machinery, high pipe blank production efficiency, uniform parison temperature, less fusion joints, low damage degree of products and high strength of blow molding products. It is suitable for the production of hollow containers with different shapes, sizes and wall thicknesses. The process is simple and the cost is low High income.

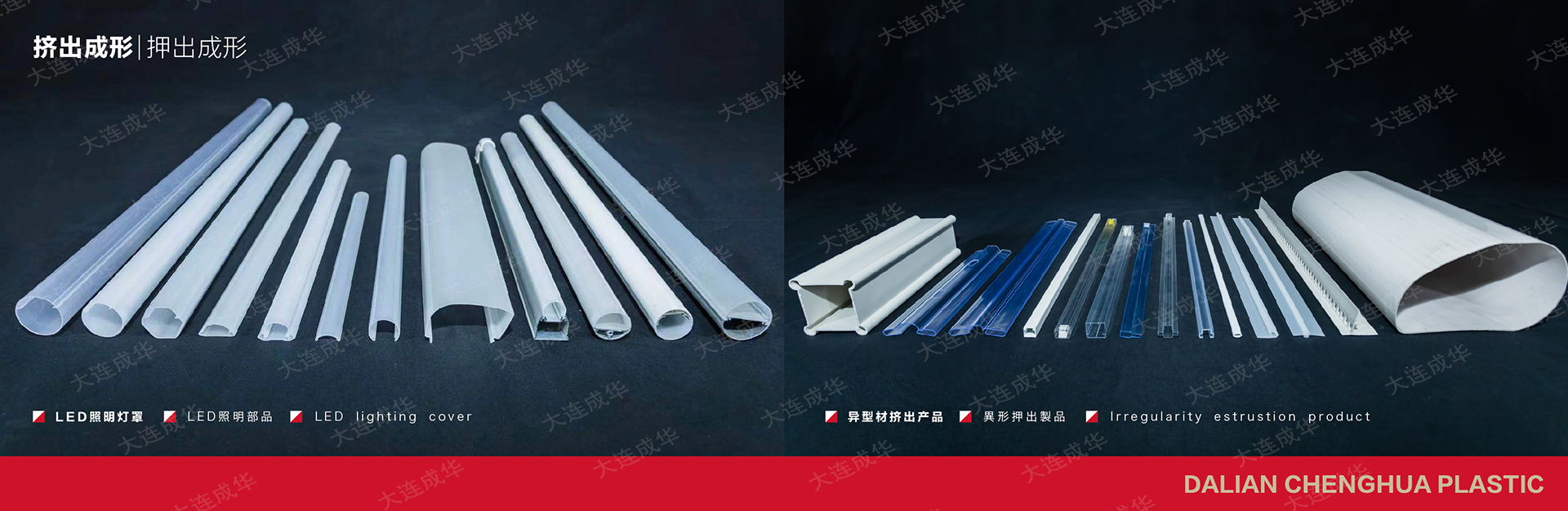

Reliable extrusion molding supplier, extrusion die is a kind of molding die, but its discharge method is realized through extrusion. It is widely used in aluminum special-shaped structure and plastic parts. At the front end of the extruder, it is used to make pipes or profiles. In short, mold is a tool used to form articles. This tool is composed of various parts. Different molds are composed of different parts. It mainly realizes the processing of the shape of articles through the change of the physical state of the formed materials.

The extrusion die can be described as an analogy: pull a ruler shaped hole on the bottom plate of the air cylinder, block the air outlet, pull out the piston, install yellow mud in the cylinder, insert the piston to suspend "air", and you can get an extruded "triangle iron". This pump is the extrusion die. In fact, the extrusion die is similar to this one, with high strength. The powder metallurgy cemented carbide is used as the "bottom plate" and the hydraulic press is used for "pumping".